Transform Your Shopfloor with Real-Time Location Data for Optimized Material Flow

In cooperation with

Enable Logistics Automation

for a Fully Digitized Workflow

The Smart Electronic Shelf Labels from ekko offer a flexible, energy-efficient solution for real-time information updates on the shopfloor. Track materials in real-time across your intralogistics process with Cavea’s MESH tracking technology, designed for cost-effective, low-impact infrastructure. Together, these technologies enable automated inventory management and dynamic, paperless visualization, providing full operational control and precision.

5 Steps to a Digital Shopfloor

1. Setup

Attach Electronic Shelf Labels (ESL) and location tracking tags to small load carriers.

2. Linking

Link the ESL to an order or material. All relevant data is visualized on the ESL display.

3. Tracking

Track the load carriers in real-time along their routes, with automatic updates to storage locations and dynamic ESL display adjustments.

4. Picking

Import picking orders from the ERP/WMS, with intuitive guidance through pick-by-light technology.

5. Assembly

Empty load carriers are automatically identified in real-time and reorders are automatically triggered.

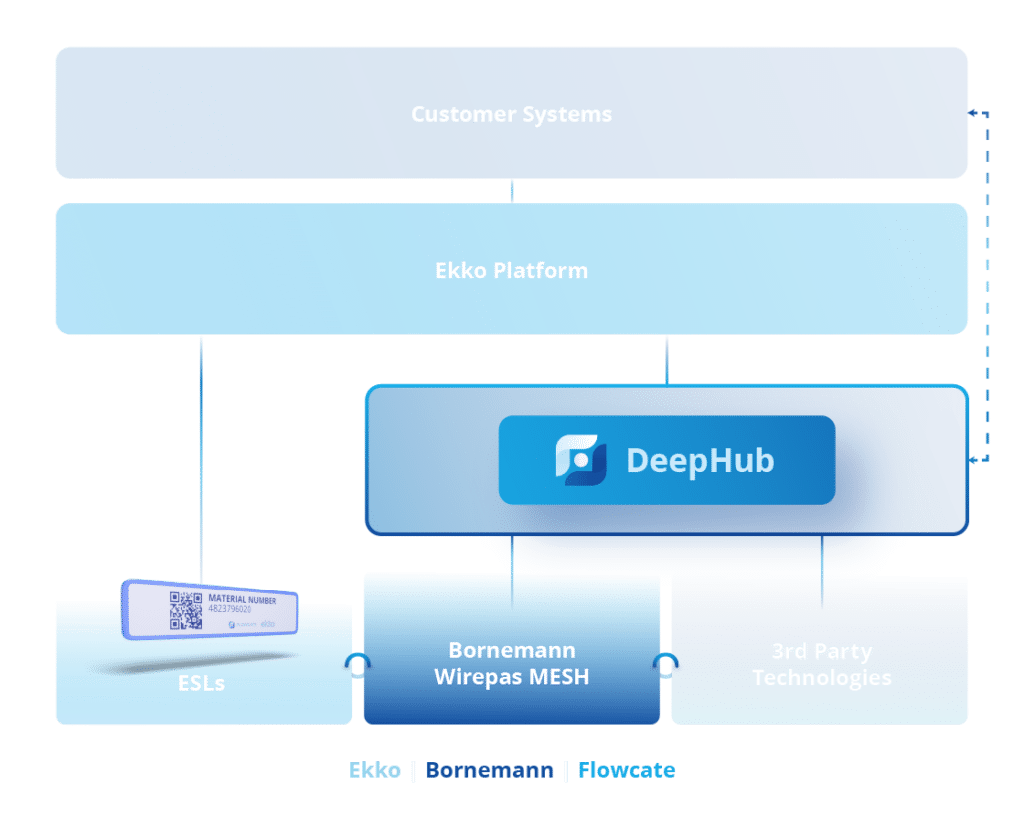

DeepHub® Inside:

Seamless Real-Time Location Data Management

At the core of this solution is DeepHub®, the leading omlox middleware, designed to manage real-time location data seamlessly across all technologies. DeepHub® enhances intralogistics automation and process optimization, allowing your operations to achieve efficient, data-driven workflows.

Full Interoperability: Connects effortlessly with any locating technology or vendor.

Real-time Geofencing: Triggers automated actions based on zones or conditions.

High Scalability: Manages thousands of connections per second, suitable for any type of operational setup.

Advanced Rule Engine: Processes location data and automates workflows with customizable conditions.