As factories become smarter, more connected, and increasingly autonomous, the boundaries between human and machine continue to blur. Collaborative robots, mobile equipment, and dynamic workflows bring new efficiency, but they also introduce new risks. Ensuring safety without sacrificing flexibility has become one of the toughest challenges in modern manufacturing.

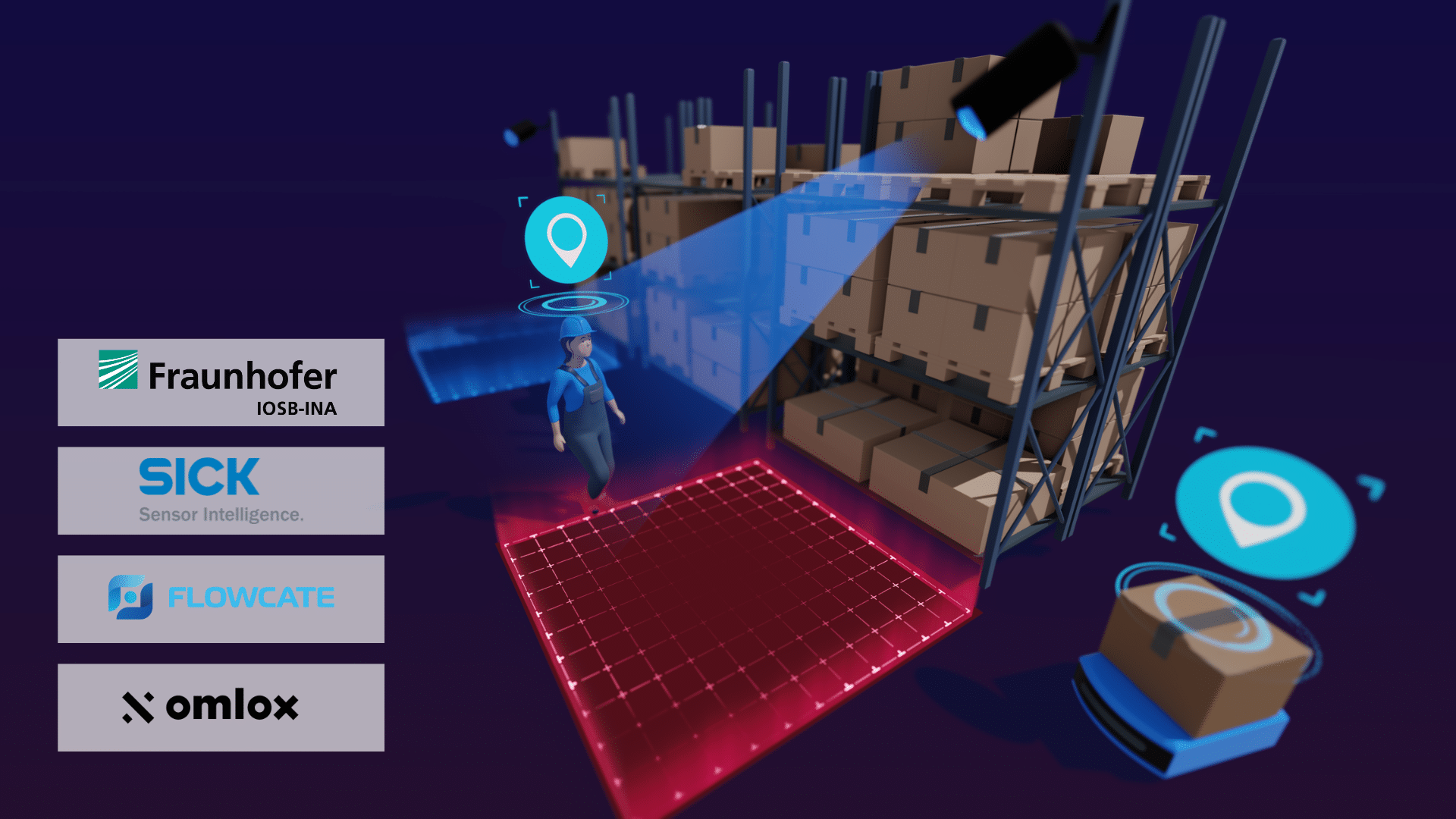

That’s where Fraunhofer IOSB-INA comes in. As one of Europe’s leading research institutes in industrial automation, Fraunhofer IOSB-INA is developing an advanced safety solution for dynamic production environments built on the omlox standard and powered by a fusion of sensor and camera technologies.

The project, known as SafeInLoc, explores how real-time location data can be used to create flexible, software-defined safety zones, forming the basis for safer, fence-free collaboration between humans and machines.

Rethinking Safety in the Smart Factory

Modern production lines are evolving faster than ever. Machines, robots, and workers share the same space in environments that must remain flexible, efficient, and safe at all times. Traditional safety measures like rigid fences, fixed layouts, and hardwired emergency systems can’t keep up with this level of agility. They slow down reconfiguration, restrict process flexibility, and ultimately limit the adaptability that Industry 4.0 demands.

Over the past few years, first attempts have been made to improve industrial safety with sensor-based tracking systems. While promising, these often fall short in practice due to environmental interference, occlusion, or single-technology blind spots that lead to unreliable detection or delayed reaction times. The result: you can’t fully rely on a single technology to ensure safety in a dynamic production environment.

What’s needed is a system that combines multiple technologies into one unified, interoperable framework that delivers accuracy, redundancy, and real-time responsiveness.

SafeInLoc: A New Era of Software-Defined Safety

To overcome these limitations, Fraunhofer IOSB-INA has developed an industry-leading solution built on omlox, the world’s first open locating standard for industry. By leveraging omlox’s ability to unify data from multiple localization technologies, the SafeInLoc project shows how a multi-technology architecture can deliver truly adaptive, reliable, and software-defined safety systems for modern factories.

At its core, SafeInLoc combines:

- UWB-based localization via the omlox Core Zone, providing high-precision tracking of people and assets across the shop floor,

- AI-driven camera systems that detect and classify people for visual redundancy, and

- omlox-certified middleware, which fuses all incoming data streams into a unified coordinate framework.

Through omlox, local position data from different devices and technologies can be transformed into global coordinates, ensuring full interoperability between systems. This fusion creates a real-time spatial understanding of the production floor, which forms the foundation for software-defined safety.

How Software-Defined Safety Works in Practice

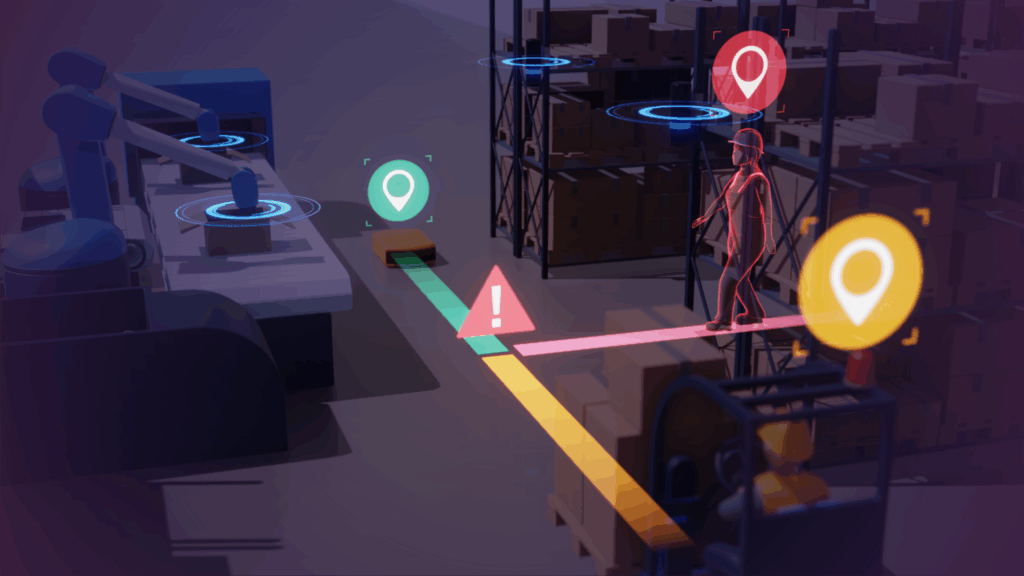

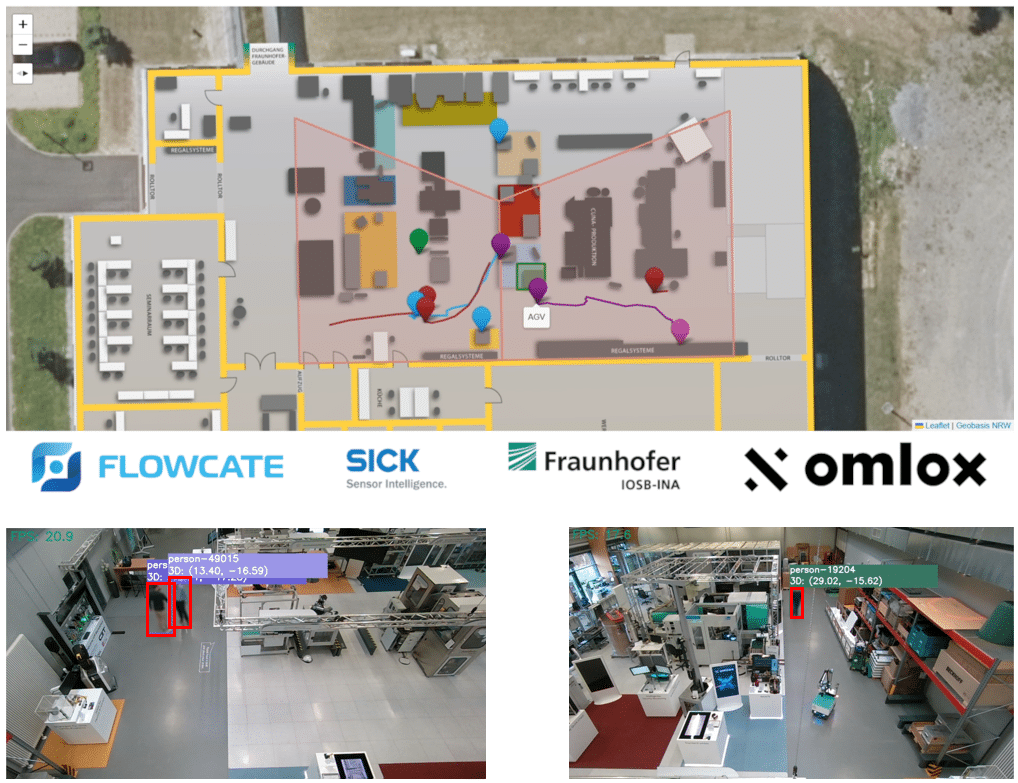

Within SafeInLoc, Fraunhofer IOSB-INA has implemented a demonstrator in its SmartFactoryOWL comprising a web-based application that allows operators to draw and configure virtual safety zones directly on the map. When a person enters one of these zones, the system automatically detects the entry, highlights the area in red, and triggers predefined actions such as alerts or automatic machine shutdowns.

Behind this visual simplicity lies a sophisticated data fusion process. Fraunhofer IOSB-INA has developed AI models in order to process live video streams to detect people in 2D images, projecting them into the same coordinate space as UWB data from the SICK Coriva System installed in SmartFactoryOWL. When multiple cameras recognize the same person, the detections are merged into a single, reliable tracker, providing accurate localization even in complex environments with visual obstructions. In the demonstrator, this is visualized as

- Red pins representing camera-based detections

- Blue pins representing UWB tag detections

When a worker enters a defined safety zone, the polygon turns red, signaling a safety event and activating corresponding actions in real time. This dynamic and multi-layered approach replaces static barriers with intelligent, responsive safety mechanisms – a key step toward fence-free collaboration between humans and machines.

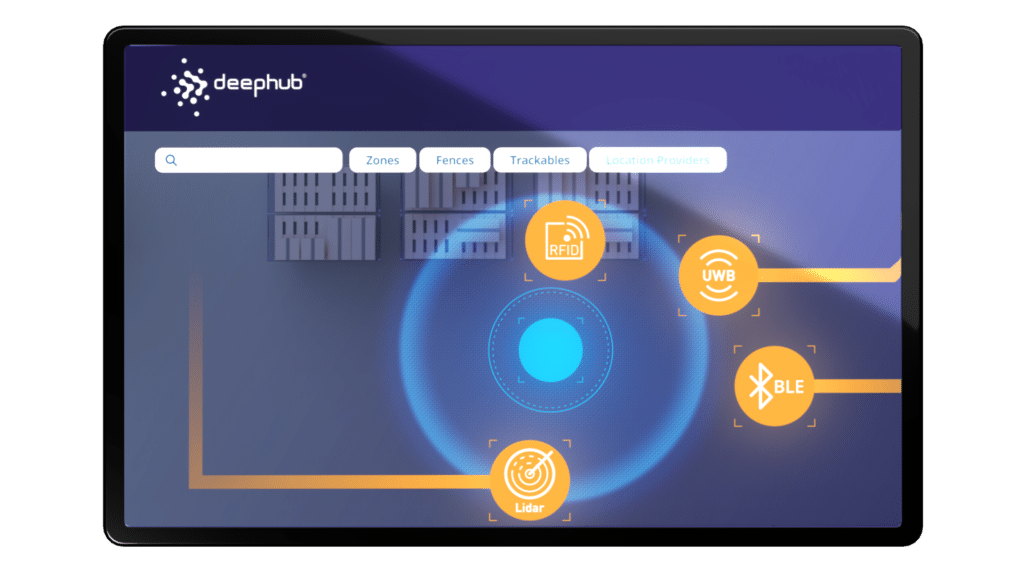

Demonstrator Powered by omlox and DeepHub®

At the heart of the SafeInLoc demonstrator installed in SmartFactoryOWLlies the DeepHub®, the premier omlox-certified middleware. It transforms and unifies location data from multiple technologies into standardized omlox coordinates, while providing

- Unified coordinate management,

- Cross-vendor interoperability, and

- Standardized APIs (including the omlox Fence API) for dynamic safety logic.

Beyond harmonizing data, the DeepHub® also enables the creation and management of omlox zones and fences, triggering entry and exit events whenever tracked objects cross virtual boundaries. These same mechanisms support collision detection, allowing the system to recognize when people, robots, or vehicles are on a collision course and trigger preventive actions in real time.

In short, the Hub doesn’t just bring location data together, it’s the backbone that makes advanced, interoperable safety systems like SafeInLoc possible.

Fraunhofer’s Role in Advancing omlox

Fraunhofer IOSB-INA has been a driving force behind the omlox ecosystem since 2021, shaping the standard through applied research, testing, and real-world implementation. The institute hosts the world’s first official omlox Test Lab, leads the omlox Safety Working Group, and continues to develop applications that bring the standard to life in practice.

The SafeInLoc project is a prime example. Deployed in the SmartFactoryOWL, Fraunhofer’s 1,200m² real-world test environment, it combines AI, UWB, and standardized location data to validate software-defined safety systems under industrial conditions. The long-term vision is to evolve this proof of concept into a certified, functionally safe solution, setting new benchmarks for industrial safety and interoperability.

What makes this approach so valuable is Fraunhofer’s ability to turn scientific research into tangible, real-world solutions. SafeInLoc isn’t just a concept, it’s a fully functional demonstrator that proves how omlox can be used to make factories safer, smarter, and more adaptable. Through projects like this, Fraunhofer helps ensure that functional safety becomes an integral part of the omlox standard, creating a foundation for safer collaboration between humans and machines.

Collaboration and Outlook on Software-Defined Safety

SafeInLoc proves what can be achieved when cutting-edge research and open standards work hand in hand. Omlox opens the door to a new generation of location-based solutions, uniting diverse technologies, providers, and infrastructures within one interoperable framework.

With Fraunhofer IOSB-INA being such an active member of the omlox community, we can expect to see more groundbreaking solutions like SafeInLoc in the future – driving progress and collaboration across industries.

If you’re interested in learning more or becoming part of this movement, get in touch with us and discover how to power your solutions with DeepHub – the first and only omlox-certified middleware.