Since the beginning of the COVID-19 pandemic, macroeconomic environments have been unpredictable and dynamic. Manufacturers are constantly confronted with new difficulties, making agility a critical success factor. In this rapidly evolving landscape, Location Data in Industrial Automation has become pivotal for the manufacturing industry as it seeks new approaches, like implementing Smart Factories, to maintain competitiveness.

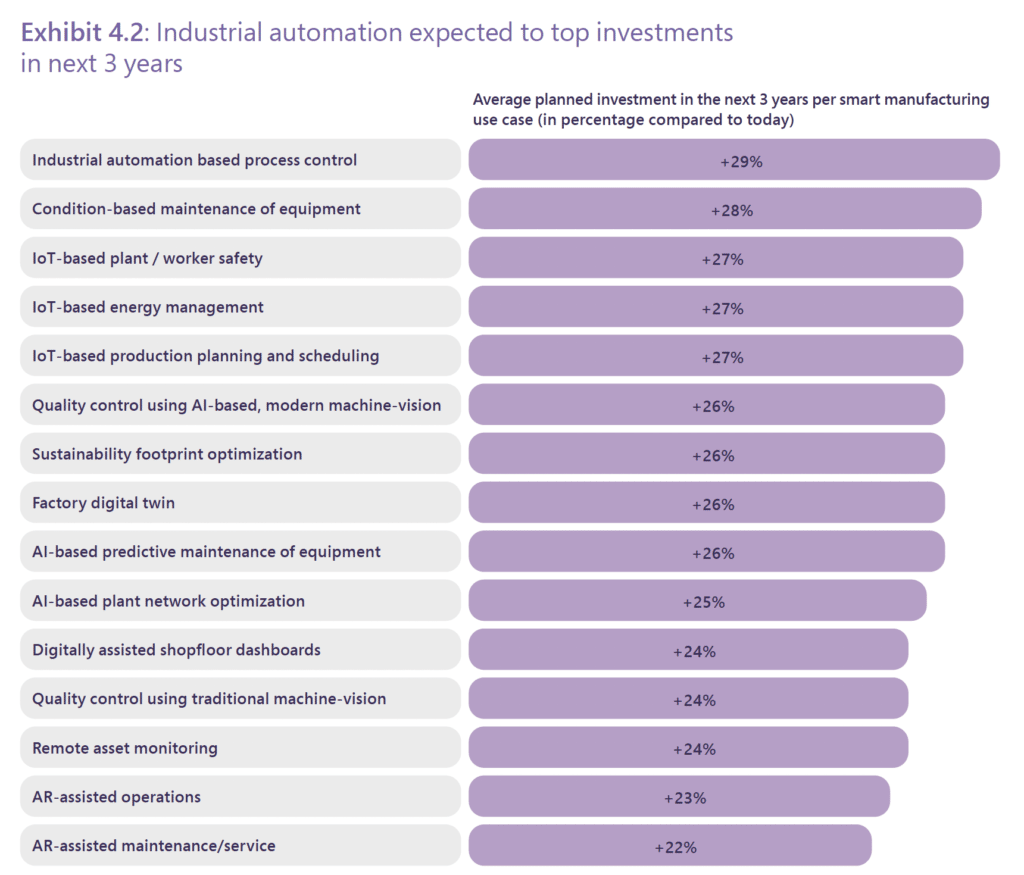

A recent research paper published by Microsoft and Intel highlights the smart manufacturing use cases expected to top investments in the next three years. We picked the five most relevant use cases where location data plays a central role and will dive a little deeper in this article. We will also be looking at the trends driving the need for change, how the Smart Factory helps manufacturers adapt, and the key role that location data plays.

Industrial Automation based Process Control

Many operations are affected by variances in materials, constraints with equipment, differences in operator skill sets, and changes in environmental factors. In order to meet the demands of the industries of the future, open software-centric industrial automation is integral.

Without real-time visibility into material flow, it can be challenging to control operations in complex logistic or production environments. Tracking the flow of materials allows each completed production step to be traced seamlessly at any time.

Tracking assets combined with the concept of “geofences” allow for automatic process control, powered by Location Data in Industrial Automation. In intralogistics, warehousing, and on the manufacturing shopfloor, there are designated areas that correspond to dedicated process steps an item has to undergo. Defining a geofence – a virtual object that spawns a defined geographical region – for each of these areas allows each geofence to get a “semantic meaning”. Entering a certain area is a “process step started” and leaving the same area is a “process was completed”. To complete the picture, a location-based system generates “fence entering” and “fence leaving” events for assets. These events can then be connected to state control systems, such as ERP or MES.

– Wolfgang Römer, Head of Product at Flowcate

Condition-based Maintenance

Condition-based maintenance involves observing and measuring various parts of an operating asset over time, in order to diagnose and prevent deterioration and eventual failure as soon as possible. Using condition-based maintenance, equipment failures can be detected before they happen, allowing maintenance to be performed precisely when it is needed. The data is usually collected either periodically or continuously by using sensors, visual inspections, performance data, or scheduled tests.

Monitoring pressure readings on water systems is an example of condition-based maintenance. Having an understanding of pressure levels allows maintenance staff to identify leaks in advance rather than at the point of failure.

Making efficient use of condition-based maintenance requires a deep understanding of your assets, including where they are located. It is also crucial to know the location of maintenance personnel. Using condition-based maintenance is one thing, but combining sensor data with real-time location information is what provides ultimate value.

Despite condition-based maintenance, the actual maintenance tasks are usually performed by staff of the parts/machinery vendor. These staff members often have little knowledge of a site and where objects requiring maintenance are located. Therefore, effective maintenance requires location intelligence and asset tracking to be efficiently managed.

loT-based Plant / Worker Safety

It is often overlooked that IoT technology can be used to enhance plant safety and security. Industrial workers are exposed to a myriad of potential dangers, as production facilities and logistics become increasingly interconnected and dynamic. Many moving elements are joining the shopfloor, which increases the risk of accidents with multiple objects in motion.

It is often difficult to determine the true state of your facility, where risks are emerging, and when things are about to go wrong without clear, accurate, up-to-date data.

Through IoT technology and big data analytics, organizations can optimize security and safety by monitoring KPIs such as injuries and near misses, equipment malfunctions, vehicle accidents (however minor), chemical spills, property damage, and employee absences. You can find out how this works in this video.

Safety for shopfloor and intralogistics workers starts with transparency of their movements: where are the forklifts and AGVs, and where are the workers. Which machinery is moving and how fast, how many workers are within a hall or designated area? These are example data points that can be delivered by an RTLS/locating system, where Location Data in Industrial Automation is crucial for data mining to achieve optimal worker safety.

loT-based Energy Management

In today’s production and logistics environments there is a constant flow of goods, machines, vehicles and workers – inbound and outbound. By nature, every movement is associated with a certain level of energy consumption. Recently, companies have been rethinking and improving their environmental and social footprint, but It takes a connected layer of technologies that can assess, track and report on everything a company does.

Tracking technologies can significantly decrease the amount of resources and equipment that can be used, as well as improving effectiveness and efficiency. To get the most out of energy monitoring, a system must be able to receive telemetry and location data, combine it, and produce a platform for subsequent analysis and insights.

The omlox standard facilitates a seamless tracking of transportation in logistics, intralogistics, and production. The modular approach, which combines technologies from different vendors, is extremely versatile. It can be tailored to any location-specific setup and may also account for material consumption on transit, thus optimizing material flows. It enables firms to meet their CO2 reduction and sustainability goals by optimising material flows.

With selected partners, we created a groundbreaking solution based on the omlox standard to make energy consumption more transparent and optimize processes in an industrial context. You can find out more on our website.

loT-based Production Planning and Scheduling

To ensure that a production line runs smoothly and efficiently, many parts must work in unison, timed to the beat of orders completed on time and error-free. Production scheduling is a critical element in this battle for efficiency and is one of the key differentiators in manufacturing planning. It organizes what a firm plans to manufacture and when.

Knowing where assets are located at any point in time is therefore a crucial component for scheduling the timely “handshake” between assets and workers.

Enabling transparency into the actual production environment is a necessity. It allows for the comparison of current processes with intended processes. A lot of the machinery within a production plant consists of moving objects: forklifts, AGVs, and small tools. Using a real-time locating system is the only way to get a complete and precise overview with full situational awareness. Decisions can then be drawn based on real information and not on assumptions.

Our Role in Providing Seamless Location Data for Industrial Automation

As we have seen, precise and universal location data from a variety of sources is the key in any of the use cases analyzed above. However, in the current technology and vendor landscape, customers have to navigate a wild-wild-west scenario with many different technologies and vendors battling for supremacy. We are the co-founders of an industry standard called omlox which is tackling this problem by streamling all location data and making it available through a standardized API.

Our middleware – the DeepHub – acts as the beating heart of the omlox standard. It allows you to aggregate and manage location data from any source and feed it to any kind of IoT solution. Looking at the statistics on the monumental need for location data in so many industrial use cases – we’re just at the beginning of our journey and are excited to be an essential driver of industrial automation.