Cleanrooms are among the most regulated environments in modern industry — especially in pharmaceutical manufacturing, where compliance, hygiene, and process control are non-negotiable. Every tool, movement, and procedure is meticulously defined. Yet even in these high-performance environments, one everyday challenge persists: knowing the current location of mobile equipment.

Whether it’s a trolley, container, or mobile device, locating cleanroom assets can be surprisingly inefficient — requiring unnecessary gowning, process interruptions, and time-consuming searches.

With a leading pharmaceutical manufacturer, Cognition Factory implemented a solution to eliminate these friction points. The result: fewer disruptions, faster workflows, and greater process visibility — all enabled by Real-Time Locating Systems (RTLS) for smart asset tracking.

The Challenge: Cleanroom Precision Meets Operational Blind Spots

In this setup, cleanrooms are critical to the client’s daily operations. But despite a highly controlled environment, recurring issues created unnecessary overhead for staff and processes:

- Mobile equipment such as carts, racks, mobile devices, transport containers, and tool containers was often stored in different zones — and some of it, particularly less frequently used items, under protective covers. Locating these assets meant walking between storage areas, lifting covers, and hoping to find the right item — often, gowning and re-gowning to enter the cleanroom unnecessarily.

- There was no simple way to analyze process slowdowns or identify bottlenecks — delays often went unnoticed or unexplained.

- Operators had to manually log process or changeover states — a tedious task, especially when using gloves and database systems.

These challenges led to increased gowning procedures, wasted time, reduced process clarity, and inefficiencies that compounded throughout the day.

The Solution: Cleanroom Asset Tracking with Built-In Intelligence

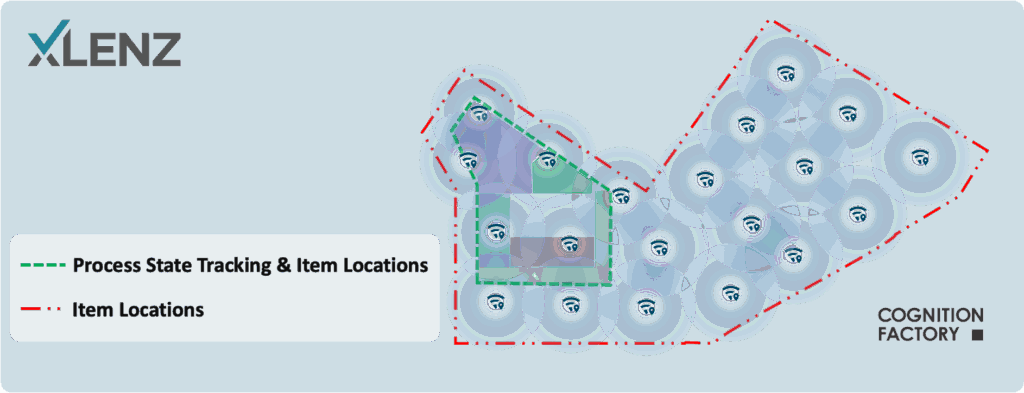

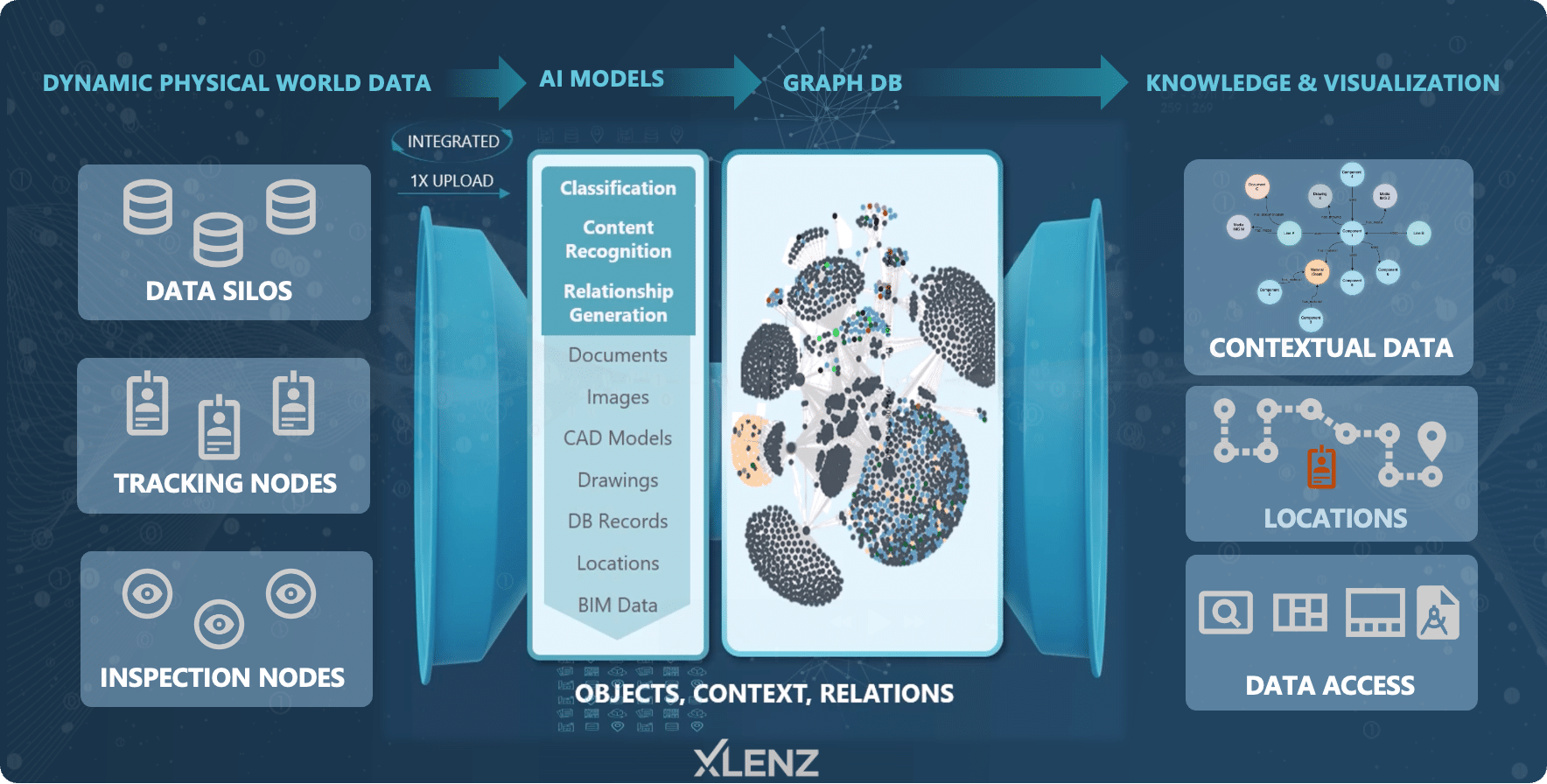

To address these challenges, the team implemented a real-time asset tracking solution using ultra-wideband (UWB) technology — one of the most advanced RTLS technologies known for its high precision and robust performance in challenging environments. Cognition Factory’s xLenz® – an AI-knowledge-graph platform – integrated with our DeepHub® middleware. The platform leverages key information from client 3D models (Building Information Models) to optimize deployment and flexibility as the environment evolves over time.

The solution provides precise, zone-based tracking of cleanroom equipment — enabling operators and systems to react based on location, without the need for manual intervention.

With DeepHub® acting as the central location data aggregator, the system harmonizes positioning data across all tracked devices and feeds it into xLenz® for visualization and analysis. DeepHub® also enables geofencing logic, which is essential for automating cleanroom workflows. When an asset enters or leaves a predefined area, xLenz® can trigger events — such as logging a changeover state, flagging deviations, or updating process dashboards. And, the system isn’t limited to UWB RTLS services. In fact, with the integration of the DeepHub®, the platform supports a wide range of location provider services, such as RFID, Bar/QR Code, GPS, etc.

This setup delivers three major advantages:

1. Automatic Process State Detection

Instead of logging changeovers or equipment use manually, the system identifies the current process status based on asset presence and movement. When a tool container enters a cleanroom zone, it may signal the start of a cleaning cycle. When a transport cart returns to staging, it indicates completion. These events are tracked in real time and seamlessly integrated into the workflow — reducing friction and increasing traceability.

2. Instant Asset Visibility Without Manual Search

Unused equipment is often stored under covers in shared storage areas. Previously, locating it required physically checking each spot. Now, staff can instantly see where each asset is — no more lifting covers or unnecessary cleanroom entries. This reduces gowning time and eliminates avoidable interruptions.

3. Process Optimization Through Data-Driven Insights

By recording every movement, the system enables detailed analysis of idle times, process delays, and asset utilization. Teams can identify inefficiencies, adjust routines, and refine layout decisions — using actual data rather than assumptions. Everyone involved gains clarity on where bottlenecks form.

Meet Our Partner: Cognition Factory

Cognition Factory GmbH, based in Munich, specializes in spatial intelligence solutions for industrial environments. Their platform, xLenz®, transforms real-time location data into usable process insight — combining AI, knowledge-graph technology, intuitive interfaces, and event-driven automation.

In this project, xLenz® provides the operational view for everyone involved — from operators to process engineers. Whether it’s locating a cart, reviewing movement history, or spotting an anomaly, xLenz® turns location events into clarity and action. What sets Cognition Factory apart is their ability to connect physical events to digital outcomes — enabling cleanroom processes to run more smoothly, safely, and efficiently.

How DeepHub® Enables Cleanroom Asset Tracking

DeepHub® is the middleware that gathers, transforms, and distributes real-time positioning data. It acts as the common layer between UWB hardware and intelligent applications like xLenz®.

Key capabilities include:

- Seamless support for multiple locating technologies

- Geofencing logic for cleanroom-relevant zones

- Real-time event streaming for automated decision-making

- A clean, unified API that makes integration fast and scalable

With DeepHub®, the system doesn’t just track — it understands, reacts, and improves over time.

Outlook: Cleanroom Visibility That Drives Better Decisions

The result is not just better transparency — it’s a tangible reduction in wasted time, manual effort, and process ambiguity. Operators know where assets are. Everyone involved gains clarity on where bottlenecks form. And teams can manage cleanroom workflows with less interruption and more control.

As pharmaceutical operations become more connected and data-driven, asset tracking is emerging as a key enabler — and cleanrooms are just one of many areas where RTLS can deliver value. Thanks to the combined expertise, cleanroom operations are no longer slowed down by what can’t be seen — they’re powered by what’s now visible.

Get in touch with us to explore how real-time location data can transform your operations.