In the world of logistics, returnable containers and pallets are everywhere — and yet, they’re rarely seen. Not in the literal sense, but in terms of process visibility. These assets include reusable transport containers, bins, cages, and pallets that move continuously through plants, between suppliers, across warehouses, and back again. With every handover across locations or partners, the risk of losing track increases.

Despite being essential to the flow of goods, container management remains one of the most manual, fragmented, and overlooked processes in the modern supply chain. Missing or delayed containers don’t just create administrative effort — they directly impact operations, triggering repacking, substitute packaging, emergency transport, or even production stoppages. While companies continue to invest heavily in digitizing production and automating transport, automated container management often lags behind, with cycles still tracked in spreadsheets, manually scanned, and reconciled only when something goes wrong.

The Challenges of Returnable Container Operations

Managing reusable containers is far more complex than it appears. It’s not just about knowing where a container was last seen. It’s about managing its entire lifecycle: delivery, return, cleaning, reallocation — all in sync with constantly changing operations.

And that’s where many companies struggle. Manual booking processes are still common practice. Containers and pallets are scanned at one location and forgotten at the next. Visibility often stops at the factory gate. Discrepancies remain undetected until monthly reconciliations reveal that dozens — if not hundreds — of assets have gone missing or are sitting idle.

The consequences are real:

Lost containers. Delayed shipments. Inflated pool sizes. Rising costs.

Why Traditional Container Tracking Systems Fall Short

To overcome these limitations, Fraunhofer IOSB-INA has developed an industry-leading solution built on omlox, the world’s first open locating standard. To address these issues, many companies have introduced technologies like Auto-ID, RFID, or legacy container tracking platforms. While these systems offer partial improvements, they still fall short in practice.

Most traditional solutions depend on fixed scanning points, structured handovers, or user compliance. But in real-world logistics environments — where containers move between locations, pass through uncontrolled zones, or are handled by third parties — those conditions rarely exist. This leads to data gaps, outdated records, and visibility that’s anything but real time. To truly solve the problem, tracking must be continuous, automated, and reliable — regardless of location, technology, or operator.

Enabling Automated Container Management at Scale

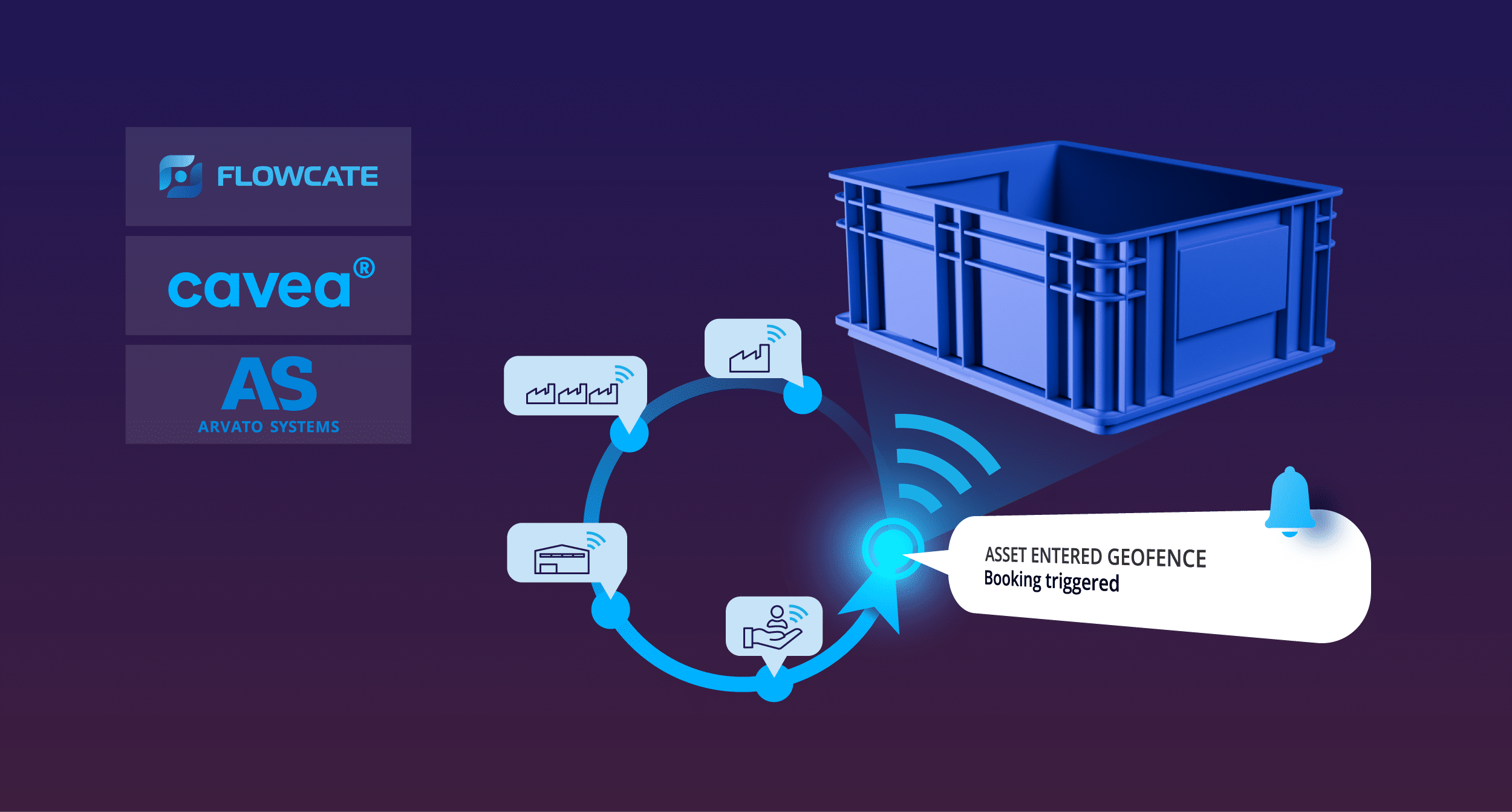

To close the visibility gap and eliminate manual processes, Arvato Systems, Cavea®, and Flowcate have developed a joint solution that transforms how companies manage returnable containers. It combines robust tracking infrastructure, seamless location data integration, and an intelligent logistics platform — delivering full transparency and control across the entire container lifecycle.

The Tracking Layer – Cavea®

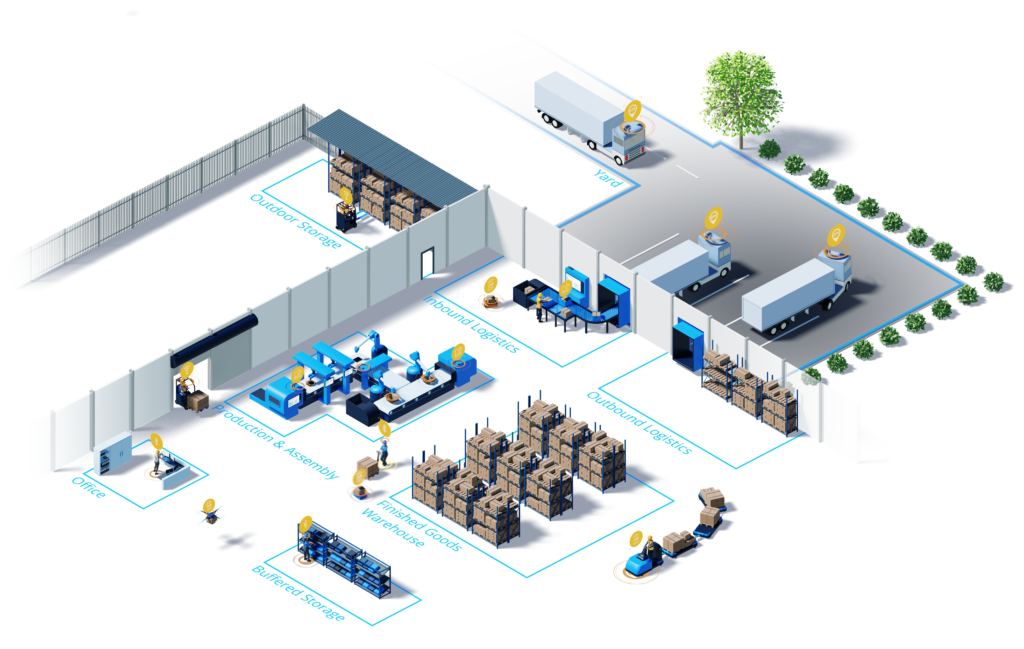

Cavea® delivers the hardware backbone of the system. Their infrastructure-light tracking network is based on Wirepas-Mesh and includes battery-powered tags and anchors, complemented by gateways. Their devices form a decentralized, self-healing mesh network that automatically forwards data through neighboring nodes — eliminating single points of failure and enabling seamless, scalable tracking across complex indoor and outdoor environments.

Even in dynamic logistics settings, Cavea® ensures containers can be tracked accurately and reliably, without the need for extensive infrastructure or IT integration.

The Location Engine – Flowcate’s DeepHub®

Flowcate’s DeepHub® sits at the center of the solution — the engine that powers seamless location data management across technologies and vendors. Built on the omlox standard, it aggregates data from Cavea®’s infrastructure and connects it to business systems in real time.

DeepHub® also enables virtual zones via geofencing, triggering automated actions — like booking events, system status updates, or alerts — as containers enter or exit specific areas. Crucially, DeepHub® allows additional or existing locating and Auto-ID technologies (such as UWB, BLE, vision, or RFID) to be integrated effortlessly, ensuring long-term scalability.

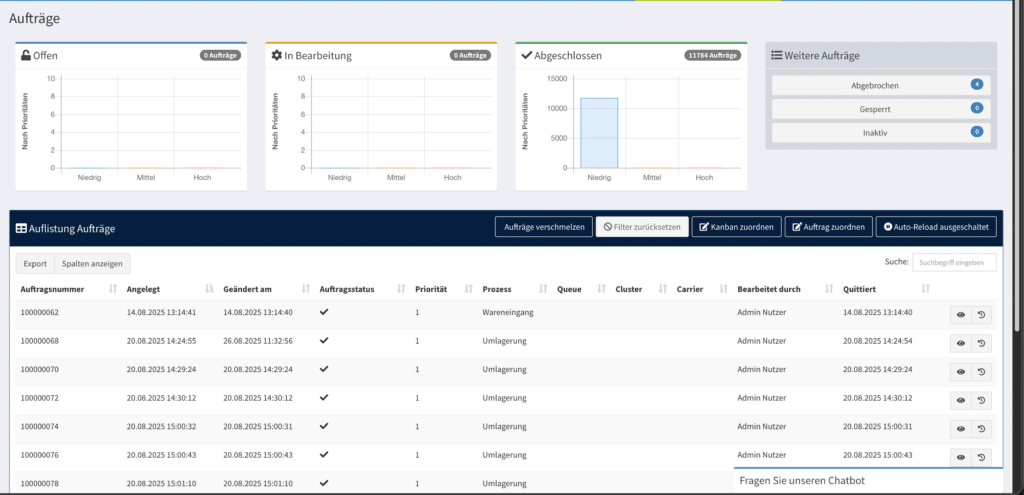

The Logistics Platform – Arvato Systems’ platbricks®

Arvato Systems’ cloud logistics platform, platbricks®, is a modular, cloud-based solution that transforms real-time location data into intelligent logistics execution. The platbricks® container management system module handles the full spectrum of container management tasks: bookings, inventory visibility, account transfers, and real-time planning.

With a 100% reliable data foundation, planners can ensure the right containers are available at the right place, at the right time, in the right quantity — avoiding repacking, substitute packaging, emergency transport, or delivery disruptions.

Designed for seamless integration with ERP systems such as SAP or Microsoft Dynamics, platbricks® also features mobile accessibility and built-in analytics, giving logistics teams full control over decentralized and dynamic container operations.

Together, the three components enable seamless, automated container management — indoors and outdoors, across internal operations and external partner networks. The result is a system where containers book themselves from location to location, their status is always up to date, and planning decisions are made based on live data — not assumptions.

Business Benefits of Automated Container Management

By replacing manual scanning, reducing administrative effort, and making every container visible in real time, companies can achieve:

- Significant reduction in container shrinkage

- Leaner pool sizes and better asset utilization

- Elimination of scan errors and booking mismatches

- Accurate planning and dynamic response capability

- Lower costs due to fewer fallback packaging or emergency shipments

In fact, benchmark results show measurable cost savings per container annually, driven by reduced losses, leaner pool sizes, and lower administrative effort. Planning processes can be accelerated by up to 60%, and manual booking tasks can be fully eliminated.

Beyond these savings, automated container management also brings indirect benefits. Since the containers themselves are tracked, companies can automatically maintain accurate inventory records of the materials inside — unlocking new levels of operational clarity and control.

Ready to automate your container flows?

Whether you’re dealing with lost assets, planning inefficiencies, or manual booking headaches — it’s time to rethink container management.

Get in touch with us to explore how this joint solution by Arvato Systems, Cavea®, and Flowcate can transform your operations.