Manufacturing and logistics are entering a new era. Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are no longer futuristic concepts—they’re central to how goods flow through modern factories and warehouses. They keep production lines supplied, accelerate throughput, and reduce manual strain.

But AGVs and AMRs are only one piece of the puzzle. True operational visibility requires orchestrating all moving elements—forklifts, pallets, workers, freight trains, and even inbound/outbound shipments. Without a way to unify them, operations remain fragmented.

This is where the concept of spatial intelligence comes in. It’s about more than tracking robots—it’s about creating a single source of truth for everything that moves. In this article that we created with our friends at Meili Robots, we highlight how interoperable fleet management and unified location data work hand in hand to unlock safer, smarter, and more scalable automation.

Interoperable Fleet Management: Meili Robots’ Approach to Smarter Fleets

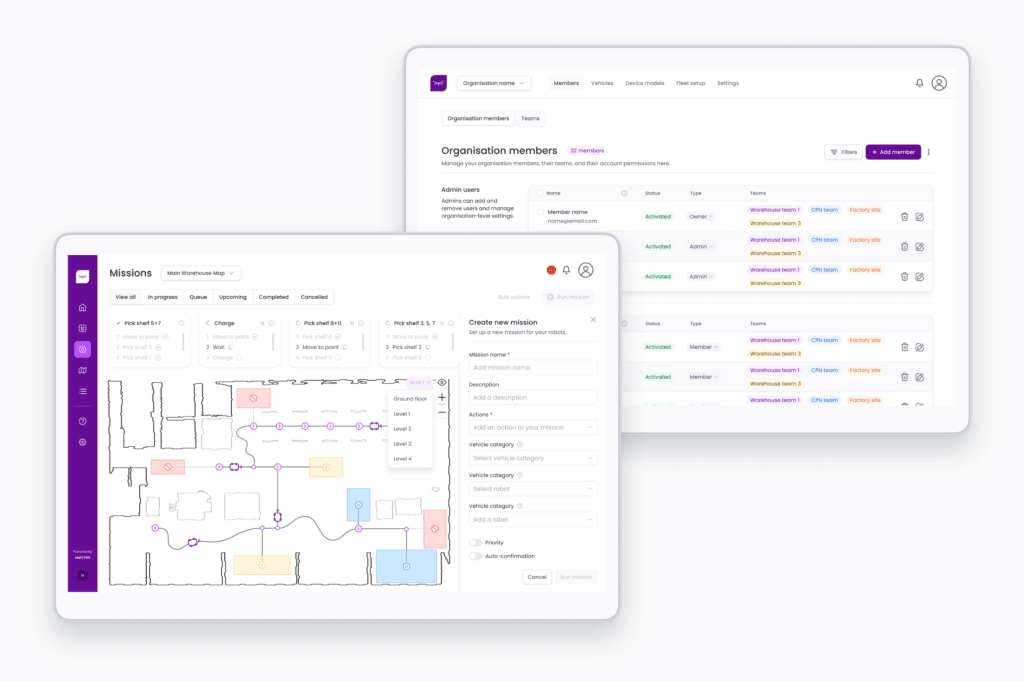

Every warehouse and factory is different, and no single robot vendor can cover every use case. That’s where our partner Meili Robots delivers the first piece of the puzzle. Built around openness, flexibility, and collaboration, their Fleet Management System, Meili FMS, is designed to make heterogeneous robot fleets—AGVs, AMRs, and beyond—work together as one.

Key capabilities include:

- Mission Management – assign and automate tasks across diverse robot types

- Traffic Control & Smart Routing – predict and prevent bottlenecks before they happen

- Flexible Deployment – deploy on-premise or in the cloud to fit IT and compliance requirements

Meili Robots follows an interoperability-first approach. Their FMS is built to work with different protocols like ROS (1 and 2) and VDA5050, and to integrate with technologies like SLAM and LiDAR that many robots use for navigation and mapping. This ensures that companies aren’t locked into a single vendor or technology stack.

With their innovative Code License model, Meili Robots goes even further—giving customers full ownership and control of their fleet management setup. That flexibility is crucial as operations scale, evolve, and bring in new vendors.

Meili Robots changes the game by making robot coordination vendor-agnostic. And that mindset of interoperability fits hand-in-glove with Flowcate’s approach to unified location data.

Unified Location Data: Making Every Asset Speak a Common Language

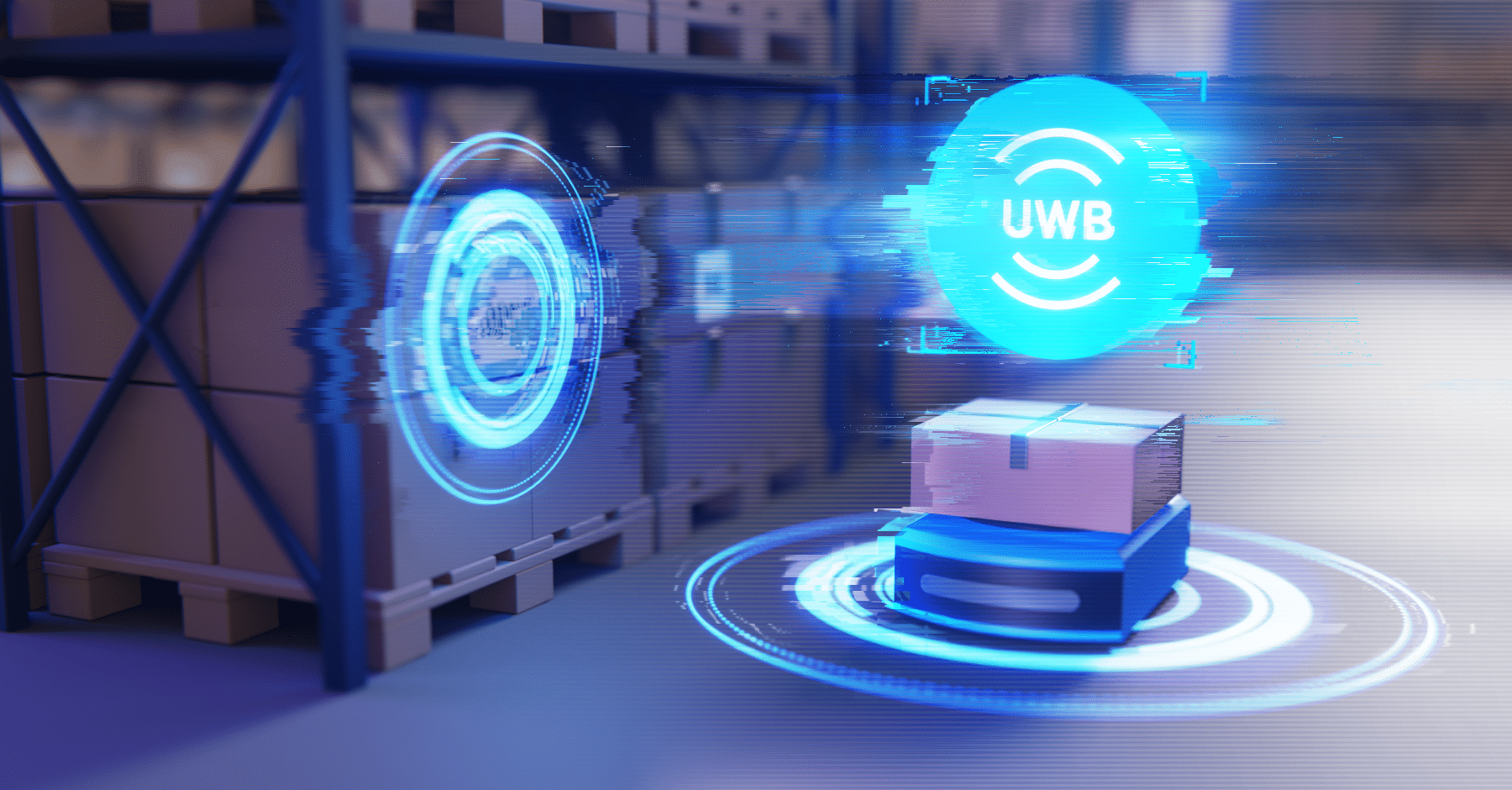

Coordinating fleets is only part of the story. To truly optimize operations, you also need to know where every moving asset is—whether it’s a forklift, a pallet, a worker, a container, or even an entire freight train. The challenge? Each is often tracked with different technologies: UWB indoors, BLE in staging areas, GPS outdoors, RFID at checkpoints, or vision-based SLAM and LiDAR directly on vehicles.

Flowcate’s DeepHub is the layer that makes all of this seamless. Built on the omlox standard, it ingests location data from any technology and translates it into one unified, real-time stream. That means every trackable—robot or otherwise—appears in a single, consistent interface that higher-level systems like Meili FMS can rely on.

DeepHub turns unified location data into actionable intelligence by:

- Cross-technology integration – unifying UWB, BLE, GPS, RFID, LiDAR, SLAM, and more

- Any-asset visibility – enabling real-time tracking of AGVs, AMRs, forklifts, pallets, workers, containers, and beyond

- Event-driven intelligence – powering geofences, safety zones, and collision alerts across all moving elements

- Flexible deployment – running at the edge or in the cloud, scaling across single sites or global operations

The benefit is clear: enhanced safety through dynamic geofencing, efficiency through real-time visibility, and scalability without integration headaches.

Asset Visibility Through Interoperability in Action

What makes this partnership such a natural fit is that both companies are built on the same philosophy: openness and interoperability.

- Meili Robots connects fleets across robot vendors, protocols, and navigation technologies.

- Flowcate connects all location data sources into a single, standardized stream.

Together, this creates a powerful ecosystem:

- One Fleet View: Robots of any brand appear in a single map, side by side with forklifts, pallets, and workers.

- Real-Time Safety: Shared geofences and instant location updates allow Meili FMS to prevent collisions, while safety zones dynamically adapt to human presence.

- Scalable Flexibility: Add new robot types, switch to SLAM or LiDAR-based navigation, expand outdoors with GPS—without changing core systems.

- Lower Integration Effort: No more custom glue code; DeepHub standardizes all inputs and feeds them into Meili’s orchestration layer.

Business Impact of Interoperable Fleet Management and Unified Location Data

The joint value of Meili Robots and Flowcate isn’t just about smoother robot coordination—it’s about elevating the entire operation:

- Faster time to value – deploy across technologies and sites without reinventing integrations

- Greater safety – dynamic awareness of humans, machines, and assets reduces risks and downtime

- Reduced costs – minimize integration overhead, avoid vendor lock-in, and leverage open standards

- Future-ready flexibility – built on omlox, ROS, and VDA5050, the ecosystem evolves with emerging technologies

Imagine a warehouse where multiple robot types—from different vendors—work side by side with forklifts and human pickers. Using Meili FMS connected to Flowcate’s DeepHub, operators can monitor and coordinate every moving element in real time. When a worker enters a shared zone, dynamic geofences automatically adjust, redirecting AMRs to safer routes. If a new robot is added to the fleet, it can be integrated within hours rather than weeks. That’s the kind of operational agility our joint approach delivers.

Building the Future of Asset Visibility with Spatial Intelligence

AGVs and AMRs are a cornerstone of modern automation, but the real transformation comes when they’re connected to every other moving piece. By combining Meili Robots’ interoperable fleet management with Flowcate’s DeepHub location middleware, companies can finally orchestrate robots, forklifts, assets, and people within a single interoperable framework.

This is what true spatial intelligence looks like: one infrastructure, many technologies, zero silos. And it’s how the future of smart factories and logistics will be built.

Ready to see what’s under the hood?

Get in touch with us to explore how interoperable fleet management and unified location data can power your operations. Let’s dive deeper together.