Modern production environments are entering a new era. The days of clearly separated work zones are over. Robots, forklifts, AMRs, and human workers operate in the same space, often in motion at the same time. The opportunities this unlocks are enormous: more flexible processes, higher throughput, and greater automation.

But with that operational freedom comes complexity. The more actors interact in real time, the harder it becomes to keep everyone and everything safe. Traditional safety systems were never built for this level of coordination. They operate in silos, lack shared awareness — and often respond too late.

So what if safety didn’t have to be isolated? What if all moving elements on the shopfloor — machines, vehicles, and people — could operate with a shared, dynamic understanding of their environment?

That question led to the development of a new kind of smart factory safety system. One designed to coordinate across technologies and actors, all in real time. The result is a new model for industrial safety and orchestration that shows what’s possible when state-of-the-art radar and real-time tracking technologies come together.

The Challenge: Keeping Mixed Operations Safe

Manufacturing floors today are complex, fast-paced environments. Robotic arms execute precision tasks. AGVs and AMRs transport materials autonomously. Forklifts navigate tight spaces. Human workers move throughout the same shared environment.

Traditional safety systems rely on isolated logic: a robot slows down in its own lane. A forklift driver depends on visibility and instinct. A worker watches their step. But without shared awareness, these systems can’t coordinate — and that fragmented approach is risky.

There are technologies that help individual actors operate more safely — like SLAM for AGVs or proximity sensors for forklifts — but they operate in isolation. Each system is designed to solve a narrow visibility problem for a specific machine, without broader context. So far, there hasn’t been a solution that brings these perspectives together into one shared understanding of the environment.

According to the Occupational Safety and Health Administration (OSHA), nearly 100 people die each year in forklift-related accidents in the U.S., and tens of thousands are seriously injured. Many of them are pedestrians. These incidents are just one example of the wider risk posed by uncoordinated movement between people, mobile robots, and industrial equipment. Even minor disruptions can lead to serious downtime and cascading costs.

The deeper issue: most operations don’t have a reliable, real-time view of where everything is — or how it’s moving. Without centralized location awareness and shared safety logic, even well-trained teams and advanced machines are working with blind spots.

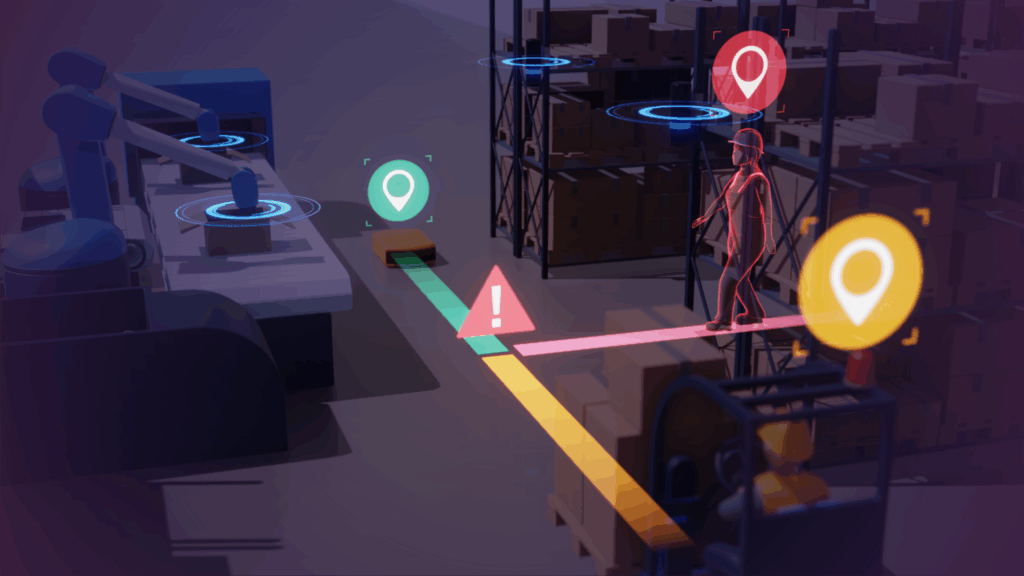

The real challenge isn’t detecting objects. It’s enabling all actors — human and machine — to operate with a shared, dynamic understanding of space, regardless of what technologies they’re using.

The Solution: A Smart Factory Safety System for Mixed Operations

Brought to life through close collaboration between Waveye, SYNAOS, Flowcate and Schaeffler, this solution combines multiple positioning technologies into one unified smart factory safety system. It enables real-time orchestration across people, vehicles, and machines.

At the sensing layer, Waveye’s industry-leading imaging radar technology detects untagged actors such as people or robots with over 99% accuracy in under 0.5 seconds. With wide-area coverage of up to 50 meters per device, it creates dynamic safety zones that adapt instantly to movement. And because it captures no visual data, it remains fully privacy-compliant.

To complement the radar and add precise identification of individual assets, the system uses UWB tracking for tagged objects like forklifts and AMRs. This enhances spatial resolution and ensures continuity, allowing the system to distinguish and track the same asset even after it re-enters the radar’s field of view.

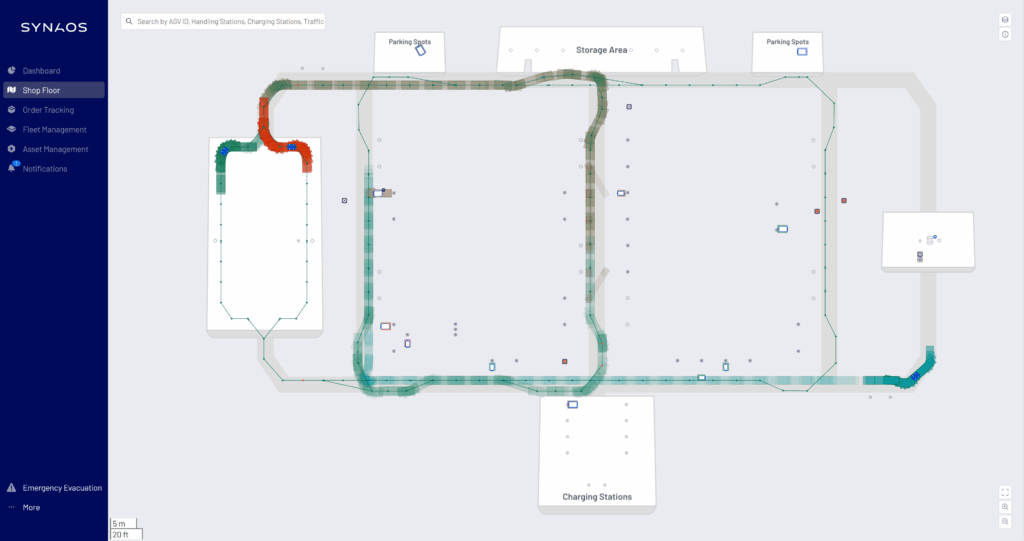

At the core of this setup is Flowcate’s DeepHub®, the premier and only certified omlox Hub on the market. Fully compliant with the omlox open locating standard, DeepHub® unifies location data from any source or vendor into one standardized coordinate system. It ensures seamless data flow between radar, UWB, and other technologies, enabling centralized visibility and control of all moving assets.

But DeepHub® goes beyond simple integration. It powers real-time collision avoidance and advanced zone management, continuously monitoring spatial relationships and triggering events based on proximity or zone entry and exit. At any moment, the system knows where everything is and how it’s moving, allowing safety logic to be executed proactively.

Built on top of this data layer, the SYNAOS Intralogistics Platform orchestrates and optimizes end-to-end material flows across all mobile robot types and shopfloor resources. By consuming the location intelligence from DeepHub®, it dynamically coordinates movement, assigns tasks, tracks assets in real time, and ensures that operations flow smoothly without compromising safety.

This combined solution doesn’t just detect motion. It enables shared spatial awareness, turning fragmented movements into coordinated action. Every actor on the floor becomes part of a connected, intelligent whole.

Why It Matters: Smart Factory Safety Systems That Power Real Operations

Dynamic safety zones

The system continuously adjusts safety perimeters based on real-time movement. It detects potential collisions before they happen and triggers avoidance mechanisms to keep people, machines, and vehicles safe.

Smarter, faster workflows

Shared spatial awareness across all actors reduces delays, enables dynamic rerouting, and keeps operations flowing efficiently.

Higher operational density

Real-time coordination allows more assets to safely operate in tighter spaces, boosting throughput without expanding floor space.

Cross-validated decision-making

Radar and UWB work together to increase reliability and reduce false positives, ensuring safe, confident automation.

Seamless interoperability

Flowcate’s omlox-compliant middleware, unifies all location data. This enables coordination across vendors and technologies within a single system.

Reduced infrastructure overhead

Radar technology covers large areas without constant tagging. UWB adds precision and context where it matters, minimizing hardware while maximizing visibility.

Privacy-first architecture

State-of-the-art radar technology from Waveye ensures GDPR and global compliance, with no visual data or surveillance risks.

Optimization at scale

The system generates actionable insights that support near-miss detection, congestion analysis, and ongoing process improvement.

Next Steps: Scaling Smart Factory Safety Across Operations

The initial implementation has laid the groundwork. The next step is scale. Discussions are already underway to extend the system into broader production environments. With larger rollouts will come concrete metrics: fewer incidents, faster workflows, better coordination.

Just as importantly, the system’s modular, interoperable design allows it to evolve. Upcoming developments include wearable integration, outdoor coverage for yards and logistics areas, and automated escalation workflows triggered by real-world activity.

What’s emerging is more than a safety tool. It’s a foundational layer for next-generation industrial automation. If you’re responsible for keeping operations safe, efficient, and future-ready, this approach was built for you.

We help manufacturers turn fragmented location data into unified, real-time spatial intelligence. Whether you’re launching a pilot, scaling a rollout, or exploring what’s possible, we’re here to support you.

Let’s talk about how centralized location intelligence can power your next move.